PCB LAYOUT, PROTOTYPING AND TESTING

About This Product

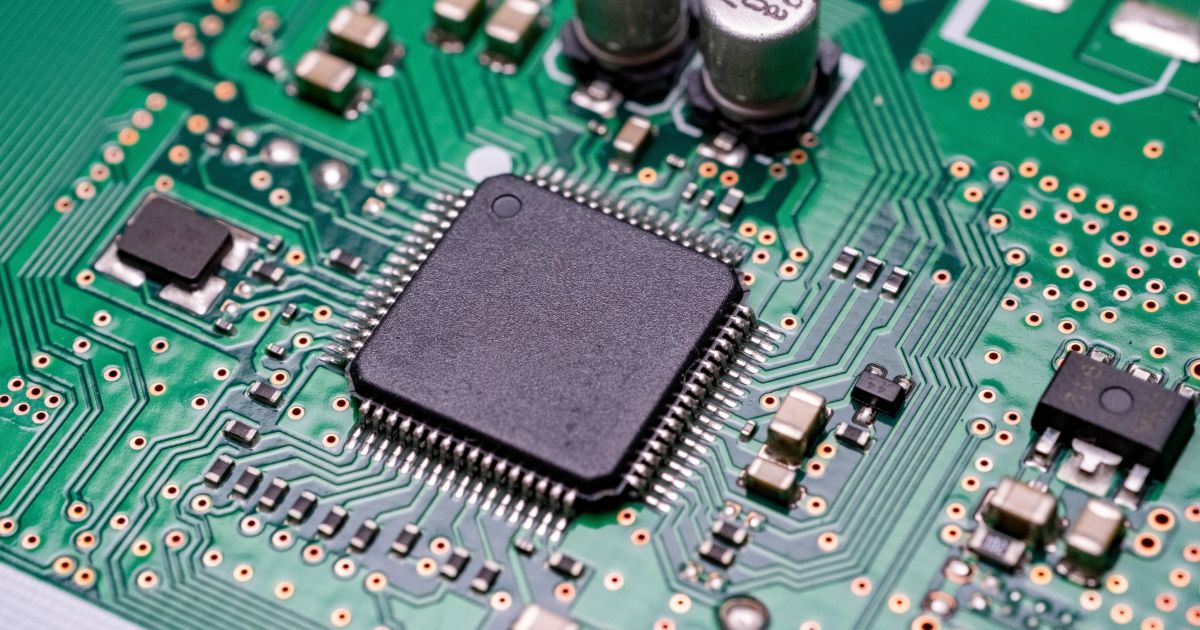

PCB Layout Engineering

We provide PCB layout services focused on functional reliability, electrical integrity, and manufacturability. Designs are developed considering signal integrity, power handling, thermal performance, component placement, and routing discipline to ensure stable operation across mixed-signal, low-power, and high-power electronic applications.

Prototyping and Assembly Support

PCB prototyping services are offered to validate layouts under real operating conditions. Prototypes are assembled using manual, semi-automatic, or automated methods based on board density and component type. Close coordination between design engineers and assembly technicians minimizes errors and reduces development iteration cycles.

Testing, Review, and Design Validation

Each design undergoes structured review and validation before release. Testing includes visual inspection, functional checks, and rework where required. Additional processes, such as conformal coating or encapsulation, can be applied to improve durability, ensuring the final PCB meets performance, reliability, and field-operating requirements.

Application Area

1. Street light controllers, timer units, and lighting automation control boards

2. Motor starters, protection relays, and voltage monitoring control circuits

3. Automatic water level controllers and pump control electronic assemblies

4. Power supply and protection PCBs used in electrical control panels

5. Industrial control boards used in APFC, ATS, and similar power products

6. Custom electronic boards for electrical equipment manufacturers and OEM products

Other Products